With the ongoing global pandemic which has sparked anxieties among the whole electronic manufacturing supply chain, finding the right PCB Manufacturing partner might become more challenging.

Here is a shortlist of what should be taken into consideration when seeking a new electronic manufacturing partner.

Pricing

One of the most crucial factors when it comes to selecting the right partner is the financial aspects. However, it should not be the most important benchmark when making this decision for your business.

Choosing the right EMS partner for your PCB assembly is a complex process that refers to not only the documentation, and production but also the supply chain.

Purchasing PCB assemblies are a complicated process. Therefore, with the attention being focused on the determining factor, which is the final price of the product, you should also look at any potential hidden costs and their consequences for your budget.

If a supplier confirms a low price for a product but lacks strong manufacturing planning competencies, this can result in delays in delivery of your product and bring unnecessary additional costs.

Poorly developed planning may result in, inadequate manufactured products and this will spark an increase of complaints from your customers. As a result, you may not only potentially face additional expenses for various types of compensation, but more importantly, face costs that relate to your brand’s credibility.

Quality

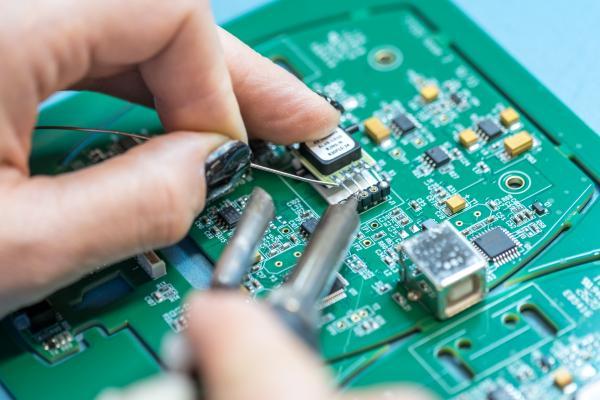

Quality is an important concept when it comes to choosing the right PCB assembly provider for your business.

Quality of production, the PCB board and the service the supplier is providing all should be taking into consideration.

Production quality ensures; the correct dimensions, accurately placed components, minimal board warping and most importantly that the board passes all the tests.

The quality of service that the supplier provides is more complex. You should ensure that they are not only responsive but also agile. The providers should consistently produce your products to the required specifications.

New Product Introduction (NPI)

New Product Introduction that meets customer expectations is a complicated process, which requires the collection of reliable information as well as the dedication of time and resources of the entire company.

Your PCB provider must use a strategy or business model to implement new products. There are few key elements that PCB assembly suppliers should take into consideration while developing your product, these are as follows:

Consistency

Data Verification

Batch Size

Assembly Supervision

Product Release

Status and Reporting

After following the process and the new product is established, your PCB providers must work on modifications and improvements. They should perform all the necessary tests and inspections to verify that the product is top quality.

Experience in the Industry

When it comes to PCB assembling; time and experience are essential. A well-developed PCB Assembly supplier takes years of practice; evolution, problem solving and technology.

Not only the experience of the organisation but also the experience of individuals involved in the key processes is important. A strong solid foundation will let the business react and adapt more effectively to any unexpected changes.

Therefore, experience in manufacturing or supply chain management is a desirable value when it comes to choosing the suitable PCB assembly provider for your business.

Price, Quality, NPI and Experience are all factors you should take into consideration as an electronic manufacturer when searching for an efficient, competitive and secure PCB Assembly provider.