Revolutionizing Drug Delivery: The Emergence of Microneedle Arrays

Harnessing BMF PµSL Technology for Medical Advances

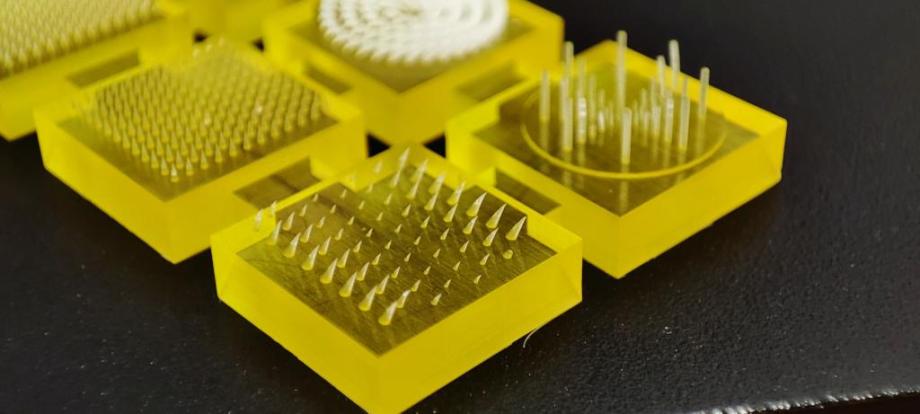

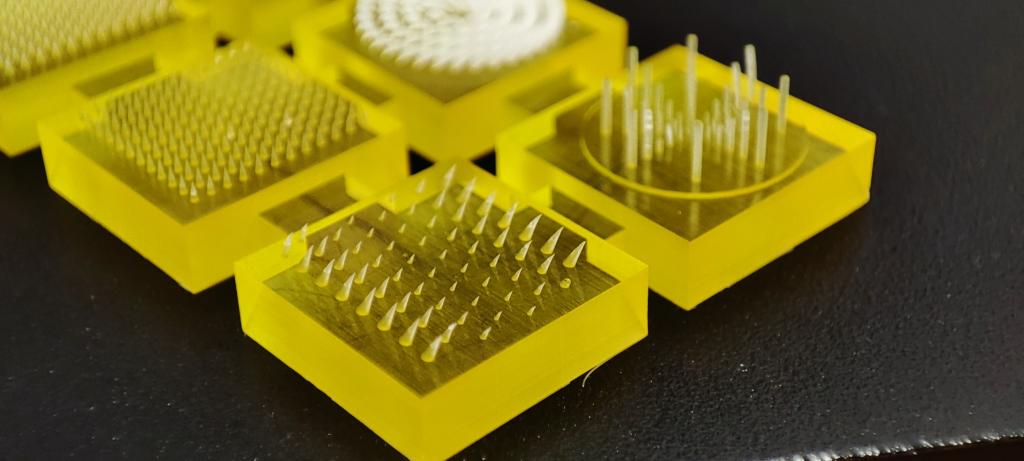

The development of microneedle arrays stands as a beacon of innovation and practicality for biomedical engineering applications. At IPFL, we're leveraging the precision and sophistication of Boston Micro Fabrication's PµSL (Projection Micro Stereolithography) technology to manufacture these groundbreaking devices for our clients.

Microneedle Arrays: A Paradigm Shift

Microneedle arrays have rapidly gained attention as a low-risk, minimally invasive method for drug absorption, vaccinations and cosmetic treatments. These arrays, composed of numerous microscopic needles, offer a painless alternative to traditional hypodermic needles, making treatments more patient-friendly.

The PµSL Advantage

The key to our success at IPFL lies in the PµSL technology, renowned for its ability to produce components with incredible intricacy and ultra-high resolution. This technology allows us to create microneedle arrays with precise, well-defined features down to the micron level, essential for effective and safe medical applications.

Accelerating the Development Cycle

One of the most significant benefits of using PµSL technology is its rapid prototyping capability. This efficiency is crucial in the fast-paced world of medical advancements, as it significantly shortens the iteration cycle and accelerates the journey from concept to market-ready products.

From Prototyping to Mass Production

The journey doesn't end with prototyping. The high-fidelity printed prototypes serve as master molds for subsequent PDMS (Polydimethylsiloxane) molding. This step is pivotal for scaling up production, allowing us to mass-produce microneedle patches while maintaining the precision and quality of the initial prototype.

The Future of Microneedle Technology

Microneedle arrays are more than just an innovative product; they represent a significant advancement in medical technology. By aligning with the trend towards minimally invasive procedures, these arrays are setting new standards in patient care and treatment efficacy. Their development and application are a testament to the relentless pursuit of innovation at IPFL.

At IPFL, we're not just creating microneedle arrays; we're supporting the future of medical treatments. The application of BMF PµSL technology in this field is a prime example of how we merge cutting-edge technology with practical medical needs, pushing the boundaries of what's possible in biomedical engineering.

Stay tuned as we continue to explore and expand the horizons of medical technology, always committed to innovation and excellence.

https://www.ipfl.co.uk/micro-3d-printing/