Cambridge Vacuum Engineering

Cambridge Vacuum Engineering (CVE) design, build, and service electron beam welding and laser welding systems.

Cambridge Vacuum Engineering (CVE) design, build, and service electron beam welding and laser welding systems.

With more than 60-years of experience, CVE manufacture process solution systems for:

-

Electron beam welding (EBW) - high and low voltage

-

Laser beam welding (LBW) - conventional with a shielding gas, or in a vacuum

-

Ebflow - welding with electron beams and a local vacuum

-

Ebflow Light - welding with a laser and a local vacuum

-

Surface modification using an electron beam including Surfi-SculptTM

CVE's headquarters are in Waterbeach, Cambridge, UK, operating from 30,000 square feet of office, manufacturing, and development space. In addition to our main design and manufacturing site in the UK, CVE has two regional offices in Beijing, China, and Massachusetts, USA, as well as a global network of agents.

“Our new welding system, Ebflow, is a disruptive technology that has been in development for 10 years. It is a major breakthrough in thick section, large structure welding and it has applications in a wide range of industries. The offshore wind projects we are involved with have the potential to provide a significant step towards the Offshore Wind Sector Deal’s ambition of increasing the UK content of UK offshore wind farms to 60% by 2030."

Products and services

Laser beam welding machines

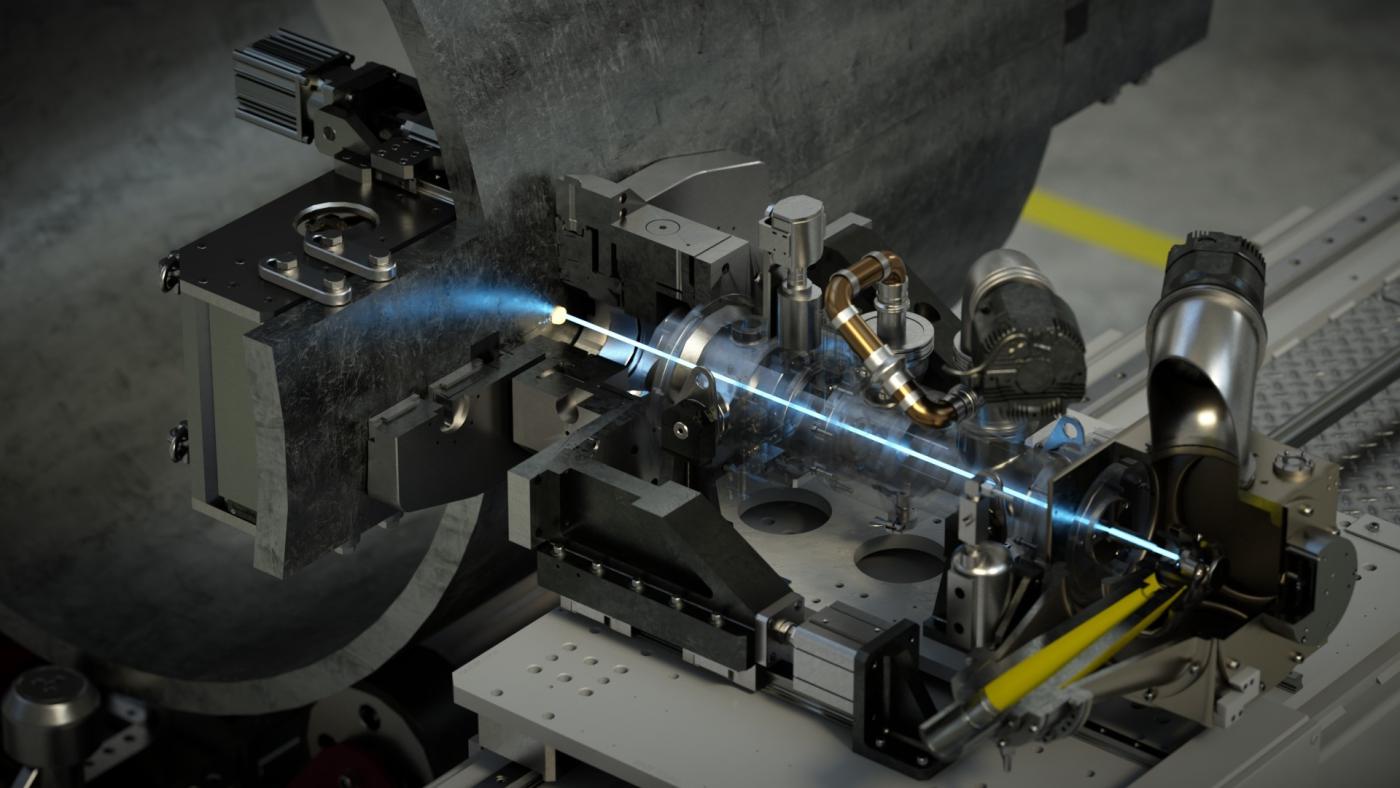

Laser beam welding (LBW) is a welding process that uses a high-power density laser beam to join two materials together, creating a deep, narrow weld.

LBW is a technique that is known for its versatility and high productivity, especially for thin section materials and welding at high speeds. Compared to other welding techniques, such as MIG and TIG, LBW has a relatively low heat input overall, resulting in low distortion, excellent mechanical properties, and minimal post-weld machining.

CVE sell a range of laser welding machines.

CVE has completed a thorough programme of development work over the past few years surrounding laser, developing systems for welding in a protective atmosphere, in a vacuum chamber and with a local vacuum.

If you are not sure which system is right for your application, please get in touch! Our machines are built-to-order and manufactured at our Cambridge Headquarters. With 60-years of process know-how in providing turn-key solutions, we find the right solution for your application.

Electron beam welding machines

Electron beam welding (EBW) is a fusion welding process that uses a high energy electron beam to join metals together, with a wide range of applications in many industries.

CVE sell a range of electron beam welding machines. Machines are built to order and options include custom and precision work handling, vacuum systems tailored to specific process needs and productivity, wire-feed, automatic joint finding, backscattered electron imaging, automatic focus, alignment and stigmator adjustment, high-speed data capture, beam probes and QA reporting. At the heart of the system is CVE’s fully integrated HMI.