What is vapour honing?

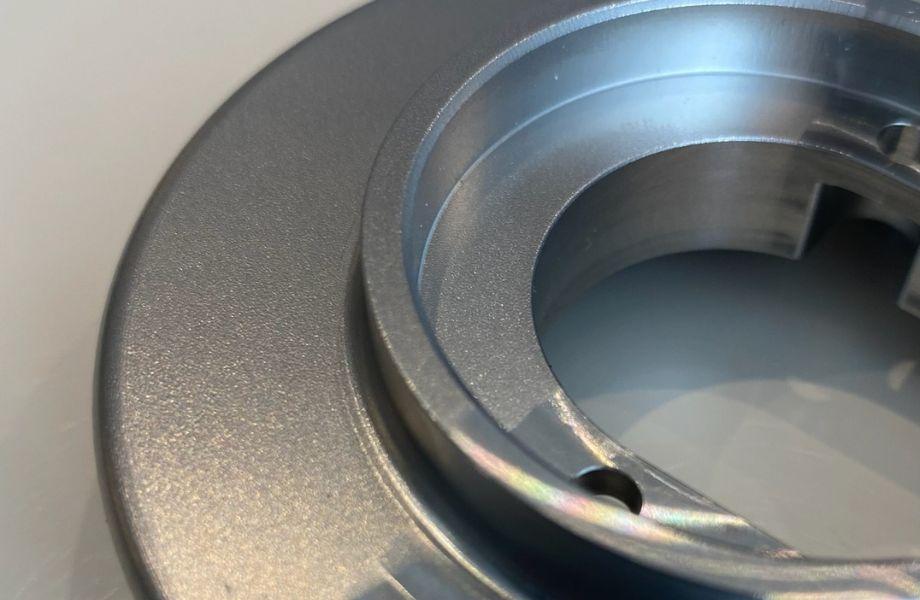

Vapour honing is similar to the bead blasting process with which we previously treated CNC machined parts, but with vapour honing the abrasive media is suspended in water. This makes the process gentler, yet the pressurised slurry is very effective at removing machining marks and burrs. The resultant surface finish has a better aesthetic than one that has been bead blasted, being smoother and more consistent. Part dimensions are unaffected by vapour honing, and the technology is safer for finely detailed parts, as well as those made from softer materials such as aluminium and copper.

If required, vapour honed surfaces can have further finishes applied, depending on the material and intended application. For example, vapour honed mild steel parts can be painted, powder coated or electroplated, aluminium parts can be anodised, and stainless steel or brass parts can be polished.

The process can utilise a variety of abrasive media but we have selected a ceramic blast media with particle sizes between 0.125 and 0.25 mm. This works well on the materials we machine, though we do not vapour hone acrylic or polycarbonate parts because it makes them appear cloudy. Also, materials such as PTFE are too soft for vapour honing, and we do not vapour hone external threads, regardless of the material. Very small parts are not treated because they are difficult to hold securely.

Please note that we are using the term vapour blasting but you may have come across one of the other terms that are commonly used for the same process, such as wet blasting, dustless blasting, vapour blasting, aqua blasting or slurry blasting.

Advantages when deburring

Compared with deburring parts by hand, vapour honing delivers several benefits. Whereas with manual deburring it can be difficult to get an even finish, vapour honing achieves a uniform finish, particularly in hard-to-reach areas.

Manual deburring also carries the risk that the tool could slip and damage a surface or critical feature, but this risk is eliminated with vapour honing.

Uniform finish

Achieving a uniform finish with conventional (dry) bead blasting can be difficult, especially on large surfaces. Because of the way vapour honing holds the blast media in suspension, the abrasive effect across the area where the slurry strikes the surface is far more even – so the resultant surface finish is very consistent.

Customers are finding that the uniform finish is particularly good for removing machining marks on aluminium parts prior to anodising.

Talk to us

If you need CNC machined parts, or would simply like to learn more about vapour honing, contact us on 01763 249760 or visit our website.