Titan will provide 3D Next Level with the ability to print very large, high-resolution parts rapidly and cost effectively. Printing large, well finished parts is a significant commercial advantage to any organisation, as parts require less post-processing and assembly time, enabling faster delivery.

3D Next Level will use Titan to create large prop parts for film and television productions, replicas for museums and exhibitions, and outdoor sculptures and street furniture.

It will also provide a valuable addition to 3D Next Level’s extensive industrial manufacturing line, supporting engineering organisations from prototyping right up to manufacture of final parts.

It will also provide a valuable addition to 3D Next Level’s extensive industrial manufacturing line, supporting engineering organisations from prototyping right up to manufacture of final parts.

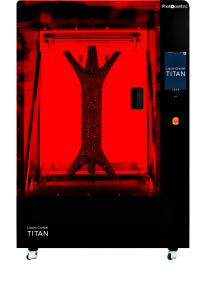

Image: The Liquid Crystal Titan’s build volume of 695 x 385 x 1200mm (27.3 x 15.2 x 47.2”) makes it possible to produce large prints in a single print.

Photocentric launched Liquid Crystal Titan at Formnext exhibition in Frankfurt where it gained massive interest as the largest LCD 3D printer currently available on the market. It has a 695x385x1200mm build volume, 91micron pixel pitch and impressive 86mm/hour print speed. It was shown with diverse printed applications from exhibition figures, automobile parts, decorative art to furniture.

Titan is part of a complete solution for large part printing with the Wash XL and Cure XL post-processing units, extensive range of resins, design software, recycling options, training and extended product warranty. Unusually in 3D printing, Photocentric was a resin manufacturer first and is vertically integrated making both printers and materials. This gives then a different view of what is needed to enable the mass manufacture of digital parts. Photocentric work directly with users to optimise their applications, creating competitive advantages over other systems.

Lennart van den Doel, Founder of 3D Next Level was looking forward to getting to work with Titan: “We are increasingly being asked to produce large prints with highly detailed finishes that can be used in films, museums and elsewhere on display. Titan will enable us to print them quickly, with outstanding detail, at a price that makes sense for this market.”

Agustin Soriano, Sales and Marketing Director at Photocentric added: “Additive Manufacturing is an essential tool for designers and engineers in product development, but increasingly one for production. Titan has a large volume build, so can print many identical versions of the same part or print one-off large pieces, opening a wider opportunity for users to be both creative and profitable.”

Top image: Back row, second left; Lennart van den Doel, Founder at 3D Next Level; top right, Agustin Soriano, Sales and Marketing Director, Photocentric