Unleashing the potential of Micro 3D Printing with the BMF PµSL System

The world of 3D printing has been revolutionised with the advent of new technologies and techniques. Today’s ground-breaking innovation is micro 3D printing, a process that allows for high precision manufacturing of microscale components. Among the leading systems in micro production is the BMF PµSL system, which offers a versatile and powerful solution for producing high-quality, and intricate parts. The benefits of micro 3D printing with the BMF PµSL system, and how it’s shaping the future of high precision manufacturing are wide-spread.

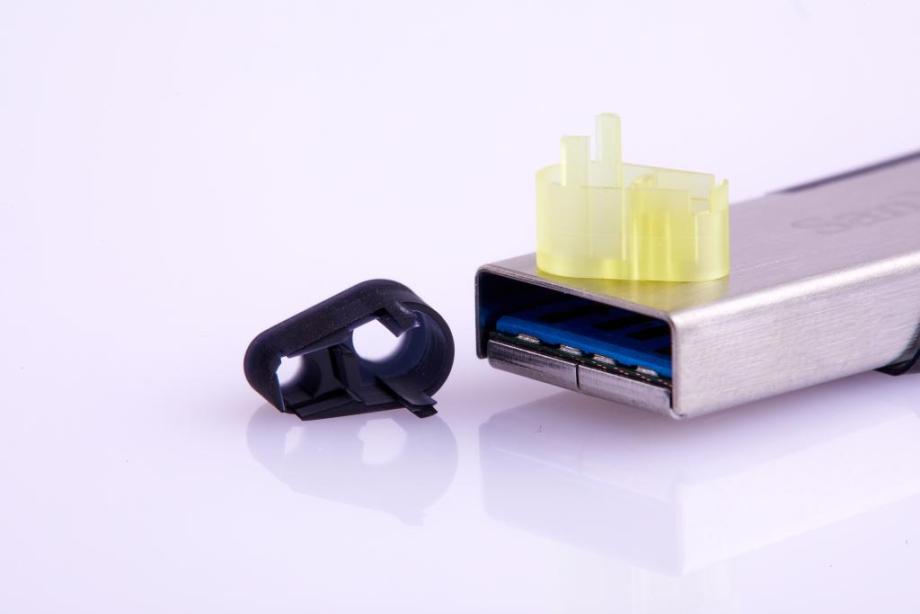

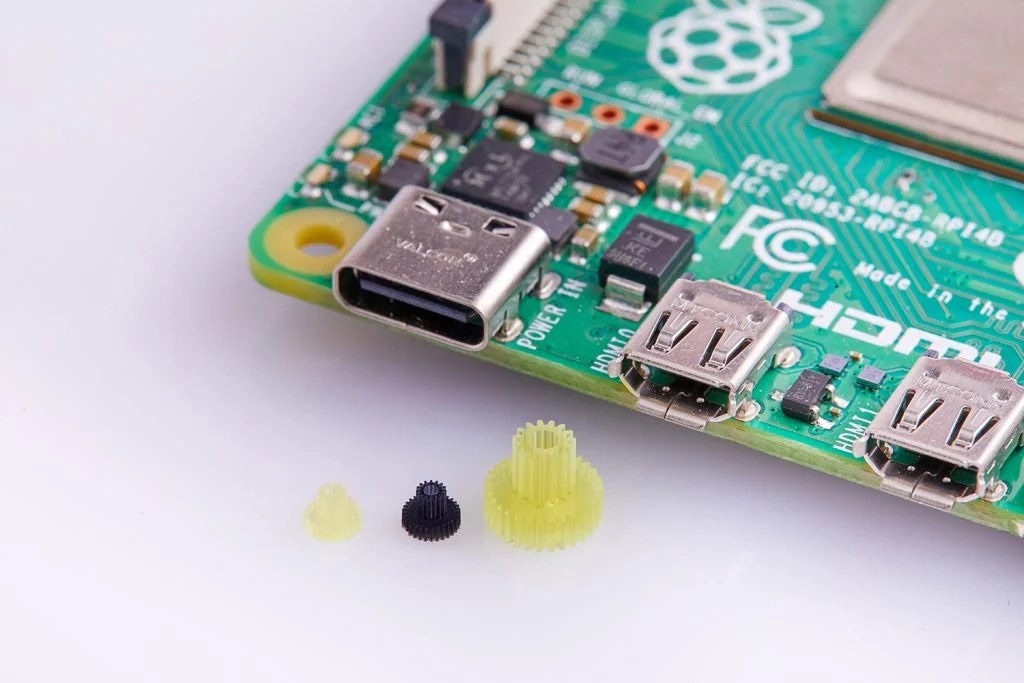

The Power of Micro 3D Printing enables the creation of incredibly detailed and complex parts, that were previously impossible to produce through traditional manufacturing methods. By leveraging the BMF PµSL system, businesses can unlock new opportunities in a variety of industries, such as; aerospace, medical, and electronics. With its high resolution and accuracy, the PµSL system allows for the creation of functional prototypes, intricate moulds, and precision parts that meet stringent requirements.

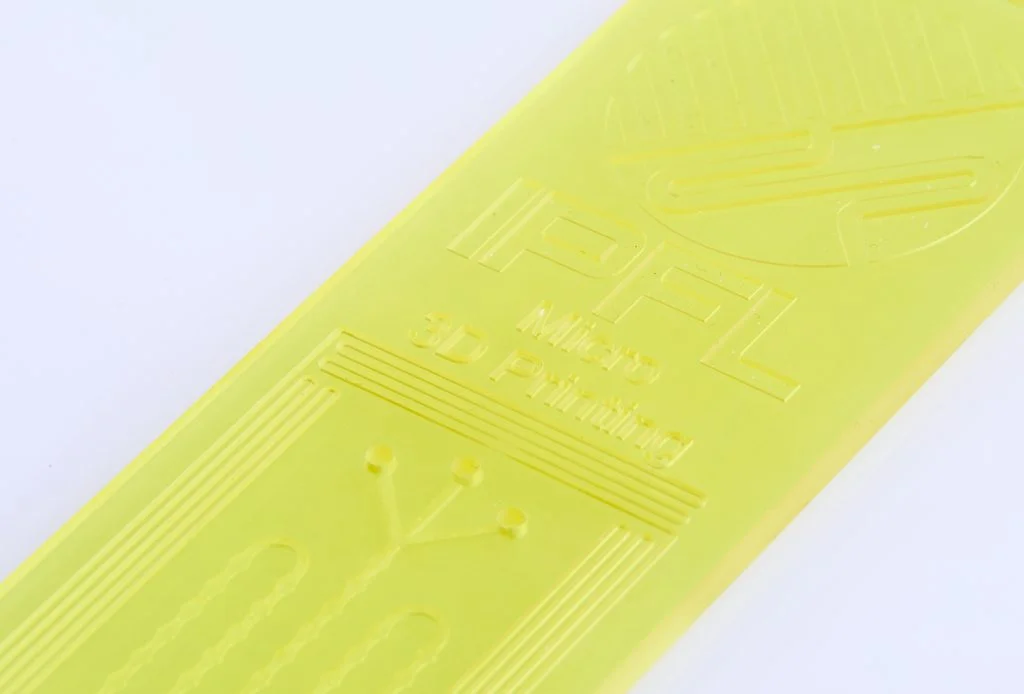

Micro 3D Printing with the BMF PµSL System by IPFL

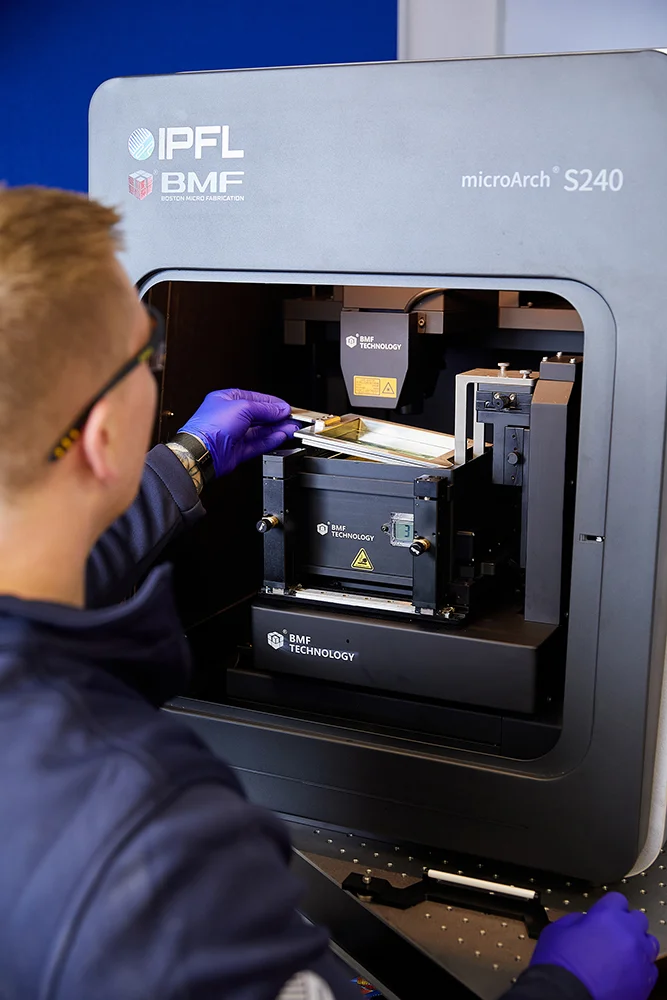

PµSL (Projection Micro-Stereolithography) is a specialized form of 3D printing, that focuses on creating high-precision microscale parts. This technique utilizes a combination of advanced materials, high-resolution optics, and precise motion control systems to achieve unparalleled accuracy and surface finish in micro production.

Here’s an overview of how the PµSL technology works:

- Digital Model: The process starts with a 3D digital model of the desired part, which is created using computer-aided design (CAD) software.

- Slicing: The digital model is then sliced into thin layers, typically just a few micrometres thick. These slices correspond to the individual layers of the 3D printed part.

- Resin Preparation: A vat of photopolymer resin is prepared. This resin is sensitive to ultraviolet (UV) light and solidifies upon exposure.

- Projection: A high-resolution projector, situated below the resin vat, emits UV light to project the cross-sectional image of each layer onto the surface of the photopolymer resin. The UV light causes the resin to solidify in the shape of the projected image.

- Layer-by-Layer Build: As each layer solidifies, the build platform moves up incrementally, allowing the next layer to be exposed and solidify. This process is repeated layer by layer until the entire part is built.

- Post-Processing: Once the part is fully printed, it’s removed from the build platform and post-processed. This may involve cleaning off excess resin, curing the part in a UV chamber for additional strength, and removing any support structures if necessary.

The PµSL technology allows for the creation of intricate parts with resolutions down to 2 micrometres, making it ideal for applications that demand exceptional precision and complex geometries. It is therefore particularly well-suited for industries such as; aerospace, medical, electronics, and micro-optics, where precision and accuracy are of utmost importance.

Boosting Efficiency and Reducing Costs

One of the key advantages of micro 3D printing with the BMF PµSL system is its ability to reduce production costs and lead times. By eliminating the need for traditional tooling, businesses can save both time and money. The PµSL system allows for rapid prototyping, enabling engineers to iterate designs quickly and efficiently. This not only speeds up the development process but also helps minimize material waste, therefore resulting in a more sustainable production process.

Experience the IPFL Difference: Precision and Expertise in Micro Part Manufacturing

In the realm of high precision, micro part manufacturing, selecting the right supplier is crucial, and IPFL stands out as a leading provider, offering unparalleled expertise in utilizing the state-of-the-art BMF PµSL technology to meet your unique requirements. Their team of dedicated engineers and technicians seamlessly integrate the PµSL system into their workflow, ensuring the delivery of exceptional results.

IPFL is also committed to upholding the highest standards in customer satisfaction and communication, making your experience smooth and hassle-free. As you embark on your micro part projects, trust in the IPFL difference to support your vision and also bring your ideas to life with precision and reliability. Experience the future of micro 3D printing with a partner you can trust.

Micro 3D printing with BMF PµSL

Finally, Micro 3D printing with the BMF PµSL system offers a multitude of benefits for businesses seeking high precision and intricate part production. Its unparalleled accuracy, reduced production costs, and rapid prototyping capabilities make it an ideal solution for industries requiring the utmost in precision and detail. As micro production continues to advance, the PµSL system is poised to soon play a critical role in the future of manufacturing, consequently empowering businesses to create products and components that were once considered impossible.